I am sure, people who are traditionalists at heart may still go for glass swimming pool enclosures. Most of them find it difficult to understand why solid polycarbonate enclosures have been trending in the recent past.

Don’t worry, I’ll explain every reason behind this.

As a matter of fact, you’ll find that for every 10 pool enclosures homeowners install, only 1 is made of glass.

In the next five years, I am sure no one will even think of installing one.

Of course, this is due to the desirable properties of polycarbonate sheets.

In this article, I want to explain to you 7 reasons why you need a solid polycarbonate pool enclosure and not glass.

1. Polycarbonate is Stronger and Durable than Glass

I think if you are looking for a material that will not break, then solid polycarbonate sheet offers a perfect solution.

Let me tell you the truth;

A polycarbonate sheet may not break even when hit it with a hammer.

This is why you’ll find these sheets in applications that require strong sheets such as storm and hurricane protection panels?

Definitely, it is a materials that will protect your swimming pool from both heavy storm and snow.

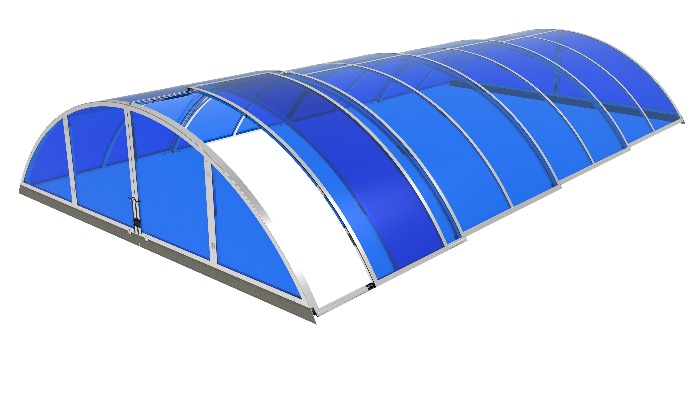

A polycarbonate swimming pool enclosure

A polycarbonate swimming pool enclosure can withstand a 900kg load distributed within 1.5m radius and a 230km/hr wind speed.

The reality is, glass swimming pool enclosures cannot handle this magnitude of weight and wind speed.

In short, a polycarbonate swimming pool enclosure is strong and durable compared to glass swimming pool enclosures.

2. Polycarbonate has Better Insulation Properties than Glass

Before I compare these two sheets, let me make some clarifications:

First, thermal insulation is a term that describes the reduction in heat transfer between two objects or two points in the same surface.

Secondly, the extent to which a surface resists heat transfer is the R-value. Therefore, a higher R-value implies a greater insulation power, and vice versa.

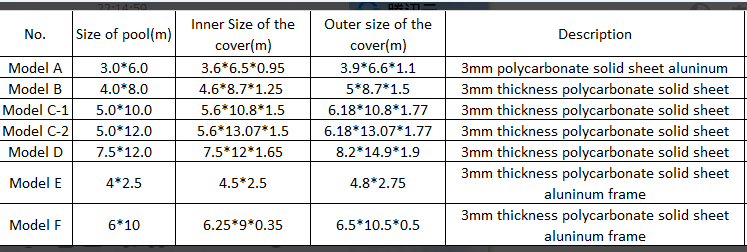

This value will vary depending on the thickness of the material in question. In fact, this is the main reason swimming pool enclosure manufacturers will specify the thickness of the polycarbonate sheets.

All swimming pool enclosure models have a 3 mm polycarbonate sheet. They have an R-value of about 1.3

I am explaining this because the amount of energy cost will depend on the insulation property of either glass or polycarbonate sheet.

That is, a material with higher R-value has better insulation properties. This will result in significant cost saving.

This implies, such enclosure will retain a reasonable amount of heat. Therefore, you don’t have to heat swimming pool water all the time.

Generally, polycarbonate materials of the same thickness as glass have higher R-value.

For instance, a 6mm polycarbonate sheet has an R-value of 1.54. Conversely, a glass panel of the same thickness has an R-value of about 1.0.

Basically, this implies that, a polycarbonate sheet has better insulation properties than glass. Therefore, it will be costly to have glass swimming pool enclosures than polycarbonate enclosures.

3. Polycarbonate Sheet is Easier & Cheaper to Fabricate than Glass

Fabrication is an important process in swimming pool enclosure manufacturing process. Adopting flexible, effective and cheap fabrication techniques is key to producing pool enclosures with sophisticated designs.

You can easily bend polycarbonate sheets of different designs

Comparing glass swimming pool enclosures and polycarbonate enclosures, you’ll realize that the latter is available in different roofing designs. Moreover, you can make customizes shapes easily and at a cheaper price.

This explains why the swimming pool enclosure cost has dropped to $2,999 (for polycarbonate enclosures). Initially, glass swimming pool enclosures could cost over $10,000.

You can bend, polish, mill or print different parts of the polycarbonate swimming pool enclosure to give it a personalized touch. This alone gives you the opportunity to have unlimited options in your outdoor space.

Fabricating glass requires sophisticated machines, which are expensive. For instance, a curved glass is very expensive than the bent polycarbonate sheets.

A reason why you’ll only find a glass swimming pool enclosures with simple designs such as gable or hip roof designs.

For this reason, polycarbonate sheet is still the best option.

4. Long-term Aesthetics of the Swimming Pool Enclosure

This describes the ability of your swimming pool enclosure to maintain its beauty throughout its entire lifespan.

A graph showing yellowing index of polycarbonate sheets with time

Glass is inherently resistant to the sun’s ultraviolet radiation degradation. In fact, this was the main reason why most homeowners were using glass.

Initially, most people argued that polycarbonate sheet could turn yellow after some time. Well, this was true back then.

Today, swimming pool manufacturers use UV-absorbing substrates that protect it from yellowing. They use a co-extruded UV-absorbing layer.

This layer protects polycarbonate sheets against degradation for more than 25 years. It is for this reason that you’ll find pool enclosures coming with a 15 year warranty.

Therefore, like the glass swimming pool enclosures, polycarbonate enclosures guarantee long-term beauty.

5. Glass Swimming Pool Enclosures are More Expensive than Polycarbonate Sheet Enclosures

So far, I have discussed some elements that influence the unit cost glass swimming pool enclosures.

These are quite evident in No. 2 and No. 3, where I discussed insulation property and fabrication.

Now, I want to introduce you to another crucial aspect that increases the cost of glass pool enclosures.

Solid polycarbonate sheet is half the weight of glass.

So, how does this weight affect the cost of a swimming pool enclosure?

First, a heavy swimming pool enclosure will require more labor. Therefore, expect the installation cost to be high.

Technicians installing a polycarbonate swimming pool enclosure

Secondly, a heavy structure will require a reinforced swimming pool deck. Remember, more reinforcement will increase the overall cost.

Thirdly, the structure will require more reinforcement. That is, beams and columns or curved sections will require more aluminum.

Clearly, you’ll see that installing a polycarbonate swimming pool enclosure is almost half the price of a glass enclosure.

6. Polycarbonate Enclosures are Safer than Glass Enclosures

Polycarbonate sheet is shatterproof. This makes it the safest material you can use for your swimming pool.

This material does not break easily to form sharp and dangerous pieces like glass.

Above shows a broken panel. Image source – 123RF

Glass pool enclosures are susceptible to breakage when hit by hard objected such as baseballs, hail, stones or snow. In fact, the enclosure may break into very small invisible pieces that are very dangerous.

These pieces can easily cause cuts therefore, you’ll be forced to drain all swimming pool water and do a thorough cleaning to remove tiny particles of glass.

The good thing about polycarbonate enclosures is that they must pass several quality tests such as the steel ball and 3 feet snow tests. This is a surety that the enclosure is safe and it will not break.

7. Polycarbonate Enclosure Offers Unlimited Options and Designs

This a crucial aspect in the modern days where homeowners are looking for fancy and high quality pool enclosures.

That is, people would wish to have both indoor and outdoor environments, depending on the weather condition. During summer, you may open the enclosure to enjoy the warmth from the sun.

On the other hand, during winter, you’ll close the enclosure; creating an indoor environment. It will protect you from cold and snow.

Therefore, with retractable swimming pool enclosures, you can comfortably regulate the environment around the swimming pool.

As a result, manufacturers have no option but to use a high quality material that can fulfill the dynamic needs of the end users. This makes polycarbonate sheet the best glazing material for pool enclosures.

With a polycarbonate sheet, they can comfortably manufacture either a fixed or retractable/telescopic pool enclosure.

A retractable swimming pool enclosure offers unmatched flexibility – you can have an outdoor or indoor environment.

Polycarbonate material is suitable for telescopic pool enclosures because it is shatterproof, strong, impact resistant and durable.

Therefore, even if you open and close your enclosure more than 5 times a day, it will not break. Moreover, its lightweight makes it easy to open and close.

Glass was mainly used to make fixed swimming pool enclosures. This is because opening and closing the enclosure may cause the glass to crack or break.

Conclusion

Clearly, there is no material that can substitute polycarbonate sheets due to the numerous benefits they offer to the end users. From the seven reasons I have listed above, it is quite evident that, glass swimming pool enclosures come with high costs and risks.

Just avoid the glass pool enclosures at all cost.

You can also learn more about different types of pool enclosures from: The Ultimate Guide to Choosing the Best Safety Cover for Your Outdoor Pool.